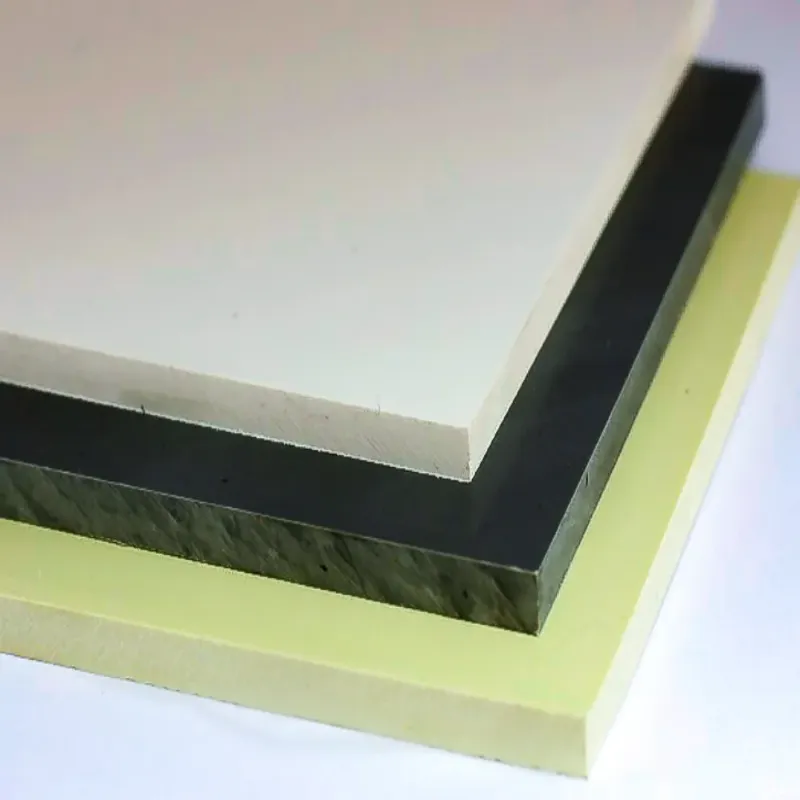

Rigid PP Board (PP Sheet/ PP Panel) – Technical Plastic Sheets

23.10.2021

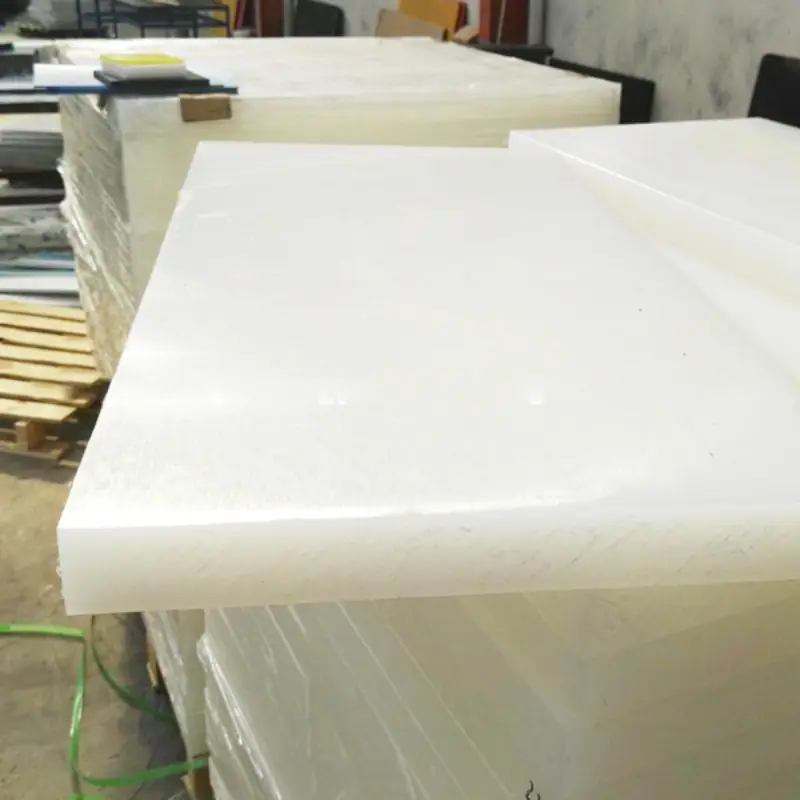

PP (polypropylene) plastic sheet made from PP pellets with safety additives, has high bearing and chemical corrosion-resistant capacity and abrasion-proof. PP sheet is heat-resistant with high temperatures (up to 100°C), higher than PVC and lighter in weight so it is used in more specific environments. PP sheet is not toxic, safe for health so people widely use in medicine and food manufacturing. We hope Phat Loc PP sheet will be the best choice of customer and replace imported products.

Applications

- Chemical Tanks

- Water Tanks

- Chemical Installations

- Pharmaceuticals and Bioindustry

- Livestock Farming & Agriculture

- Aquaculture / Fish Farming

- Swimming Pool Construction

- Food production

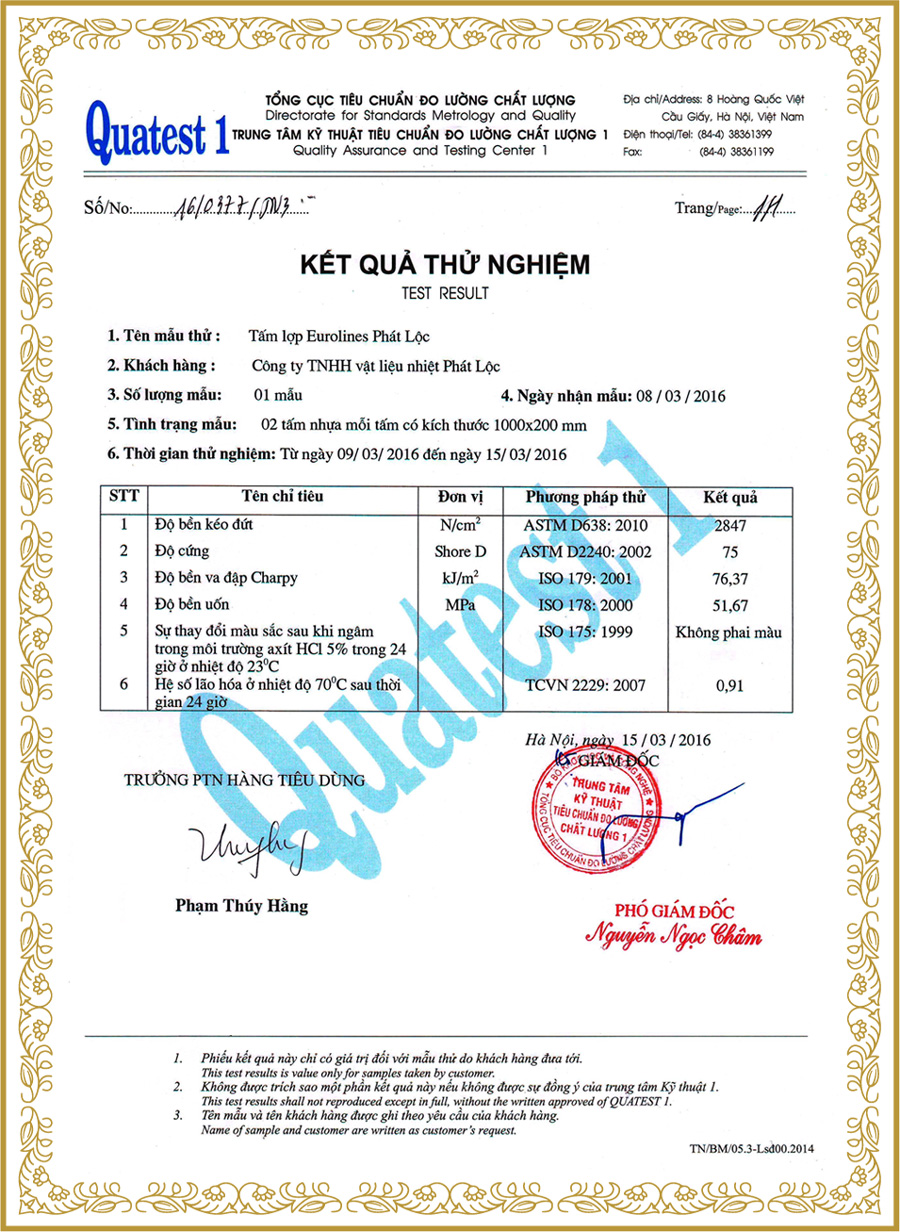

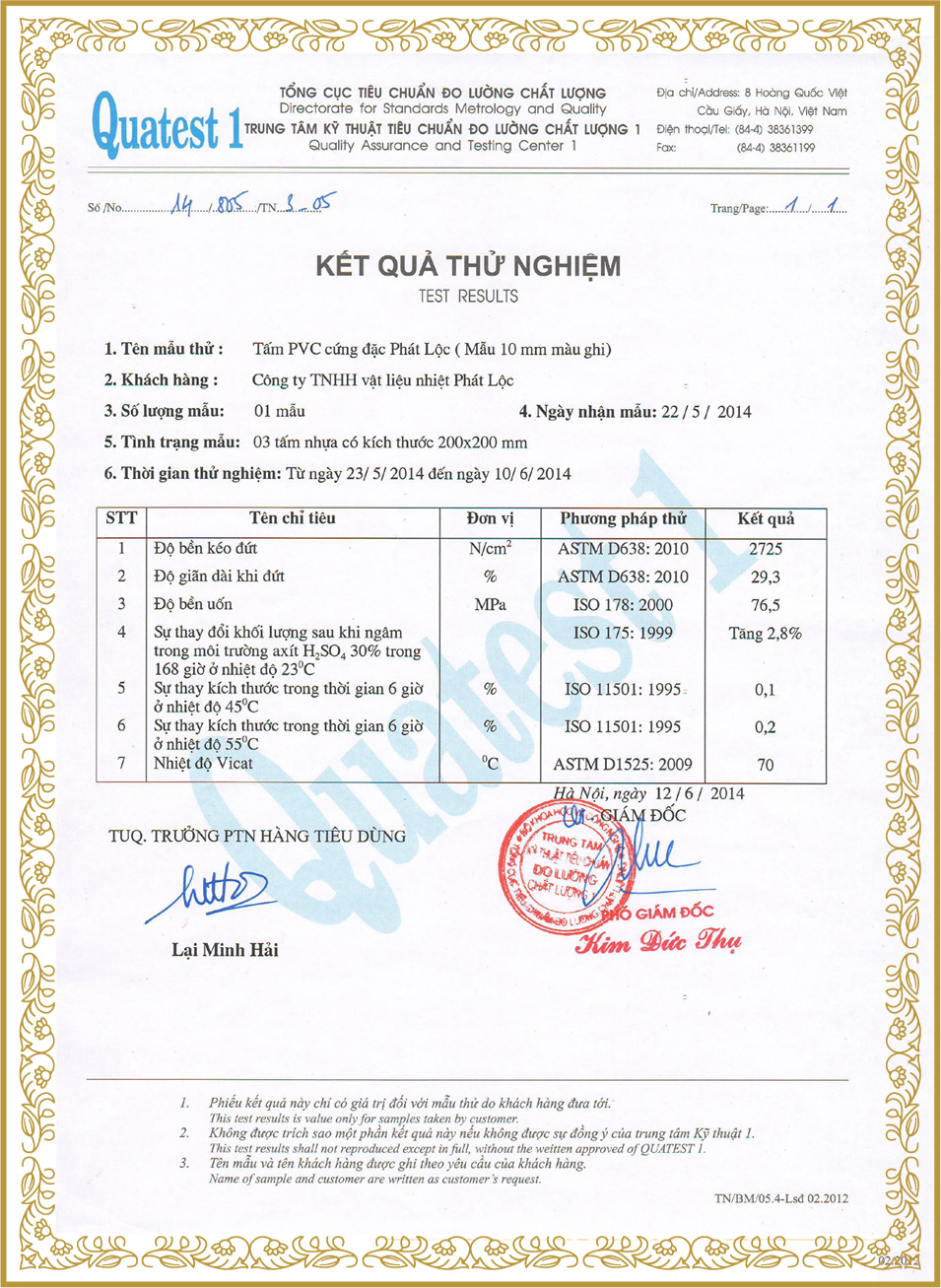

Technical specification PP sheet

| NO | TECHNICAL CRITERIA | UNIT | PARAMETERS |

| 1 | Reliability Tensile | N / cm2 | 2500-3200 |

| 2 | Elongation at break | % | 25 – 33 |

| 3 | Reliability bending | Mpa | 45-90 |

| 4 | The change in size in 6 hours at 55 ° C | % | 0.01 – 0.1 |

| 5 | Vicat temperature | ° C | 100 |

Application of PP sheet

- PP sheet making chemical tanks, plating

PP sheet making chemical tanks, plating: PP tanks have the ability to withstand high concentrations of chemicals. PP tanks commonly used in Crom plating, pickling copper solution. Advantages of PP when making chemical plating tank is that it has the expansion and better temperature resistant than PVC, however PVC is capable of better antioxidant.

- PP sheet making air intake system

PP sheet making air intake system: in many environments, the working temperature requires relatively large, straw-section is not too large, plants will choose PP for processing. Currently, exhaust systems in the plants – manufacturing chemical are usually made from PP plastic sheet.

- PP sheet for industrial cutting boards, cutting mold food, pharmaceutical.

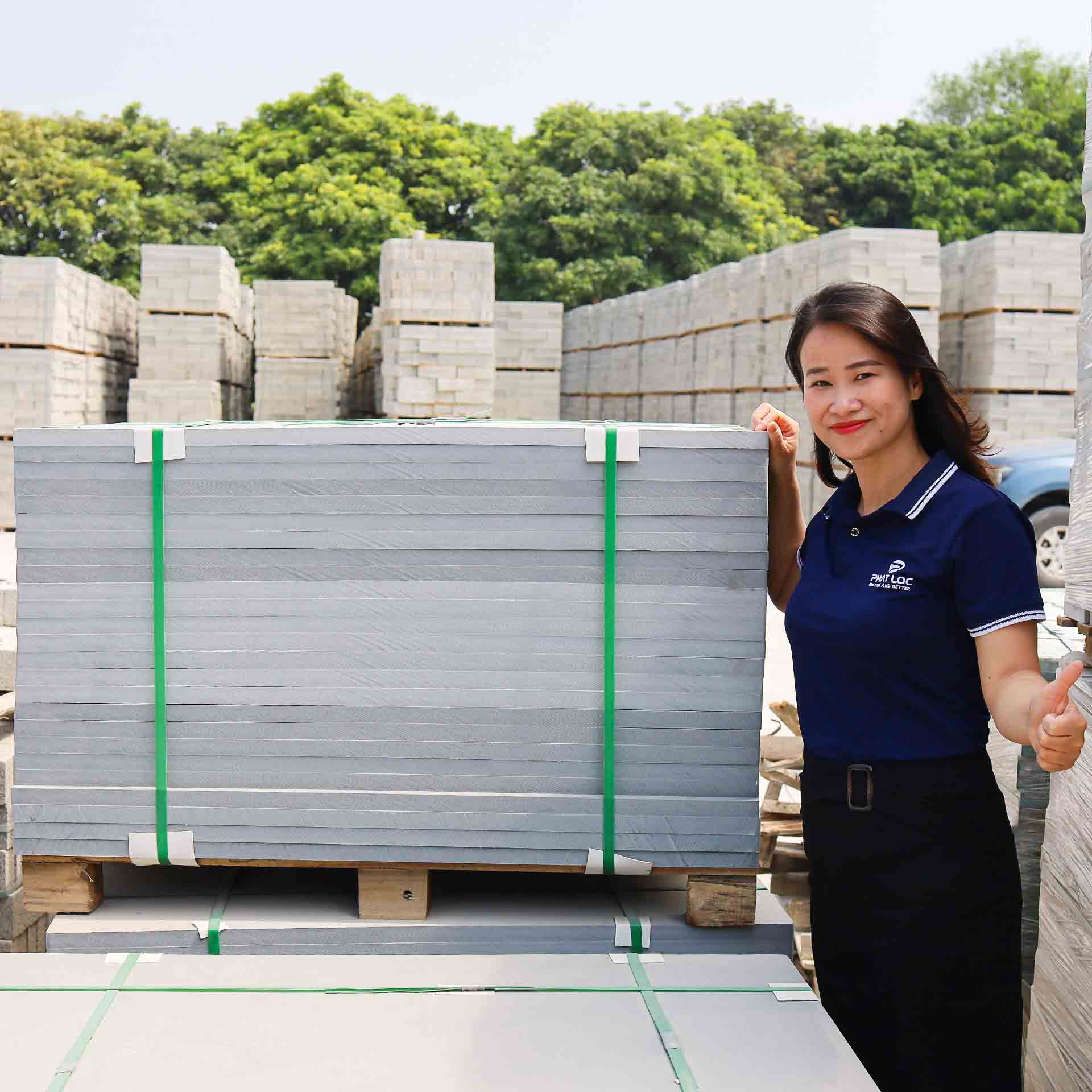

PP board Phat Loc Factory