Why are corrugated iron sheets?

06.05.2021

Wavy roof is a common shape of the corrugated iron roof, this seems to be a characteristic design of this line of construction materials. However, have you ever wondered why the corrugated iron roofs have wavy shapes, why manufacturers must necessarily produce products with wavy shapes, and why are not diverse in style? design or not?

If you are wondering about this issue, the answer will be answered shortly.

The reason for the corrugated iron sheets

Roofing is a material commonly used in many construction projects such as houses, industrial factories … It protects the public from the effects of external factors. Depending on the type and technical factors, each type of corrugated iron will have different thicknesses and technical standards. Normally, the thickness of the corrugated iron is calculated in zem, if the larger zem, the more durable and thicker the sheet. Currently, most types of corrugated iron on the market are produced with a thickness of 2 – 5 zem.

The reason that the corrugated iron roof is designed with a wavy shape is because of the following reasons:

- Mechanical: According to the engineers, the wavy design will help increase the bearing capacity of the product. This is also the reason that the corrugated iron roofs have better bearing capacity than straight corrugated iron. Not only that, this design also helps to reduce noise, limit the influence of the outside environment on the interior space, especially when there is heavy rain.

- About heat: Tole is used to protect the building from the impact of external factors, so the sheet is a place directly affected by sun, wind, rain … Especially, when the weather is hot, with high heat radiation, the sheet will expand. With straight corrugated iron, when expanding if there is not enough area, the sheet will break or the fixing screws will come off. Meanwhile, corrugated iron has a wavy structure, creating a space to help expand the corrugated iron well, limit the impact on the structure of the roof and do not cause screws to detach.

Basic structure of the corrugated iron roof

To better understand why the roofing sheet has a wavy shape, let’s learn the basic structure of this product. The corrugated iron roof consists of 3 parts: the frame, the truss part, the roofing sheet and the screw system. Specifically:

- Frame system: is the largest load-bearing part of the project, ensuring the durability to withstand extreme weather conditions such as hail, storms and floods.

- Trusses and roofing system: Depending on the area of corrugated iron, the purpose of use, the needs of the paratroopers, the truss and roofing system will have a certain change. Currently, instead of choosing traditional materials, to protect the sun and heat the building, contractors often choose eco-corrugated iron over other products.

- Screw system: Usually choose the type of fasteners made of chromium-plated stainless steel. Because they have high hardness, weather resistance, help to limit rainwater seepage inside.

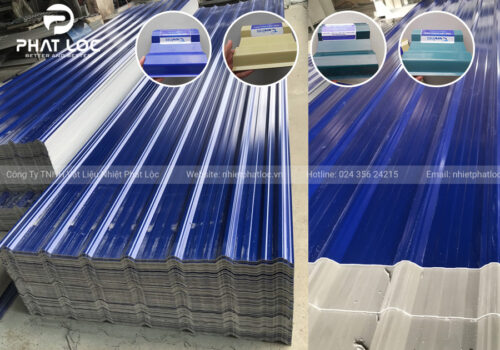

Types of roofing are commonly used today

To meet the design requirements, usability to use, roofing sheet products are available in many different types such as tile imitation roofing, cold corrugated iron, light corrugated iron … Specifically:

- Corrugated and imitation roofing sheet: Designed in wave form in western tile style, suitable for roofs with steep slopes or designed in the style of villas. Helps significantly reduce the load on the ribs of the roof, columns and foundations compared with conventional brick roofing.

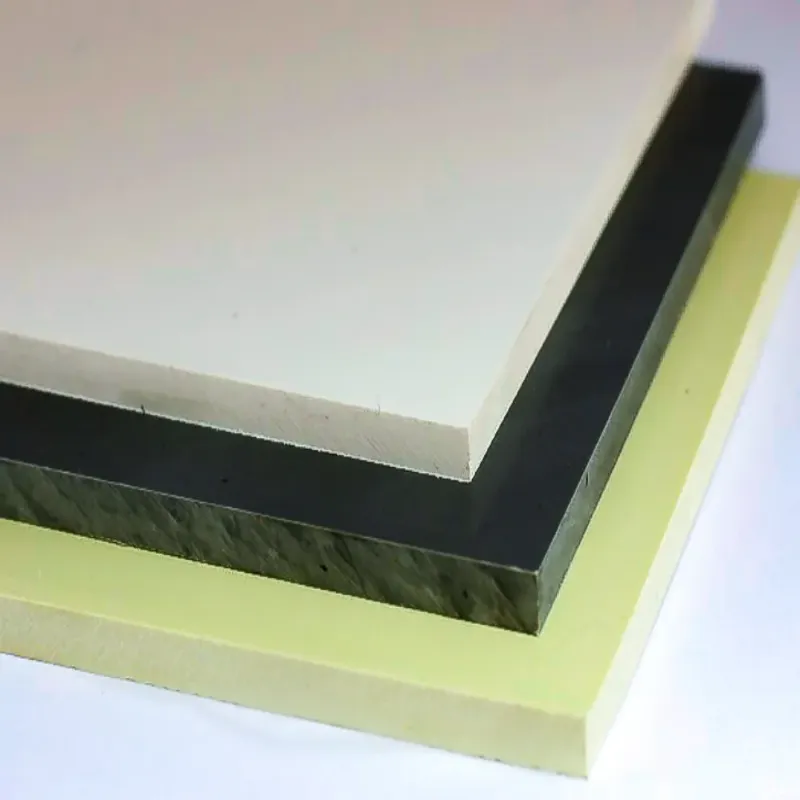

- Cold iron: Able to reflect sunlight with 2 main components: aluminum and zinc. Resistant to the effects of the environment, can create compounds at cut edges or scratches. Not only that, the product is also more resistant to corrosion than conventional products.

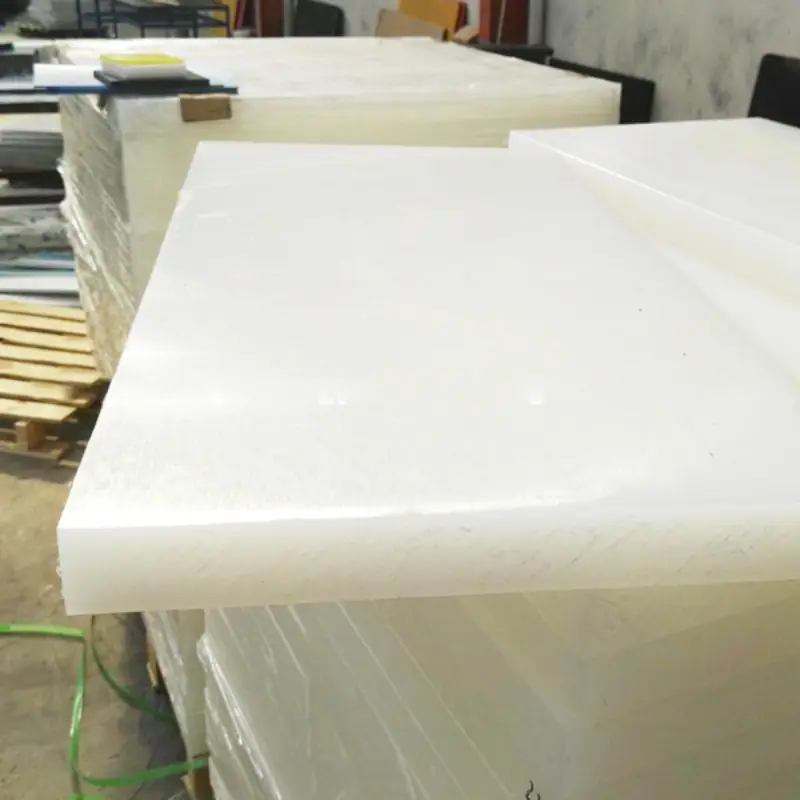

- Sunlight: Plastic sheet for light is an increasingly popular product in today’s projects due to its low cost, high durability, and suitability to weather conditions in Vietnam. The solution is suitable for projects that require a lot of light such as factories, manufacturing plants. Capable of getting light from 85 – 90% with an anti-UV coating to protect health. Not only that, the product is also capable of heat insulation, sound insulation, not oxidized, abrasive, does not react when exposed to acid, alkali …

Effective alternative to traditional corrugated iron

Despite its wavy design, which limits the impact of environmental factors, traditional products still have disadvantages such as the ability to reduce noise and reduce heat transfer is still extremely low. This is the main reason why many people do not like the metal roofing because it is quite hot, and it is easy to lose heat.

For now, however, there’s absolutely no need to worry about this. If you need to get light, sound and heat insulation for the building, you can use light sheet. If you do not have the need to take light, want beautiful works, high durability aesthetics, long service life and ensure sound insulation, you can choose eco roofing.

Eco roofing or ecological tile is a product made of Bitumen and synthetic fiber designed in the form of corrugated iron sheets that are waterproof, noise-proof, light-weight, and do not rust over time. In particular, this product also has extremely durable properties, because it is made of synthetic resin, so it is very convenient to move and install. Not only that, this product line is recommended to be environmentally friendly, safe for the health of users, and can be used in almost any project, including in harsh climates.

Above is some information to help you answer the question why the corrugated iron sheet is not the other shape. If you are looking for a place that provides new generation roofing sheets that are environmentally friendly, keep up with the trend of modern society, don’t forget to contact us.

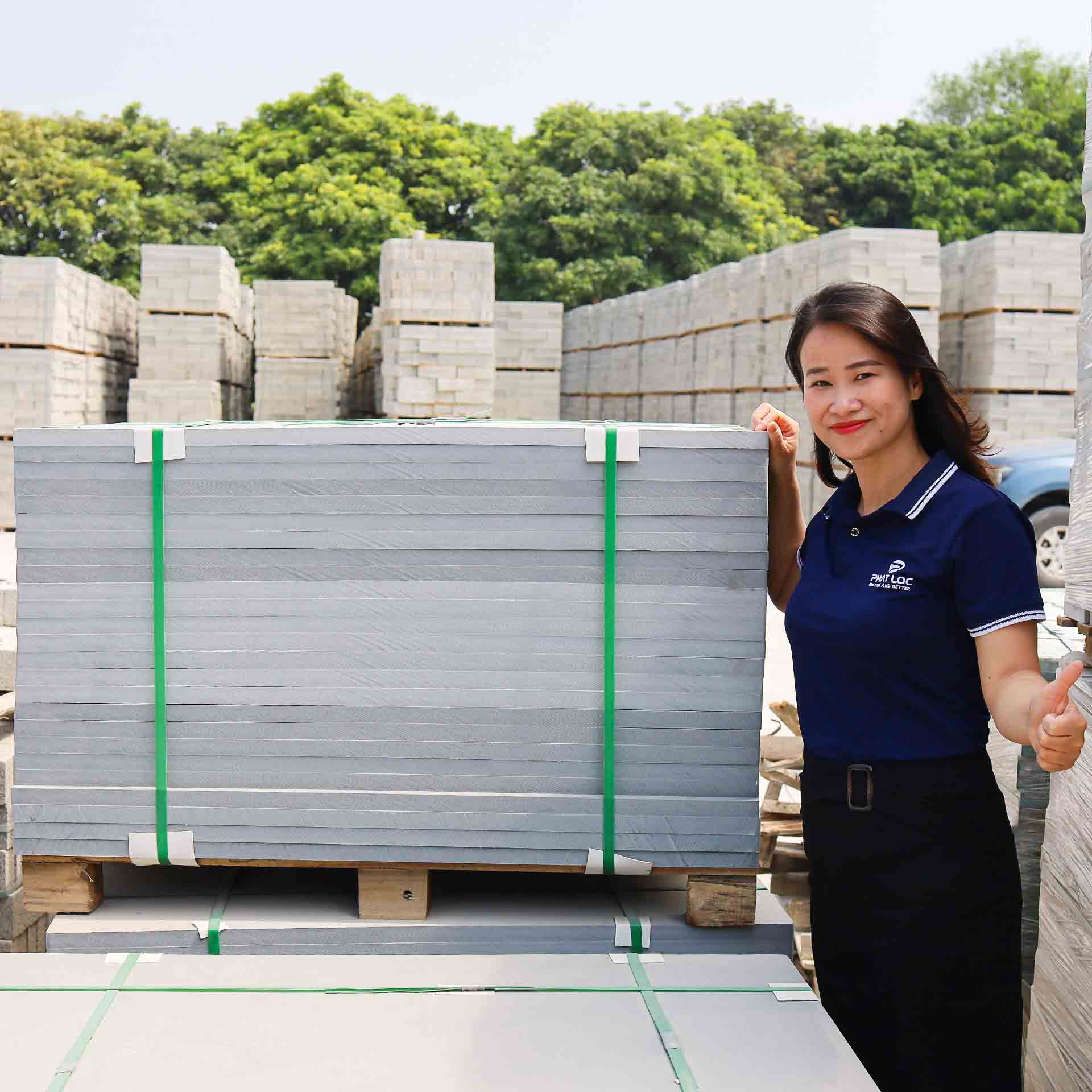

Phat Loc specializes in providing all types of corrugated iron roofing available in the market such as eco roofing, light sheet, soundproof roofing … If you want to buy corrugated iron, please contact us. for best advice and quotation