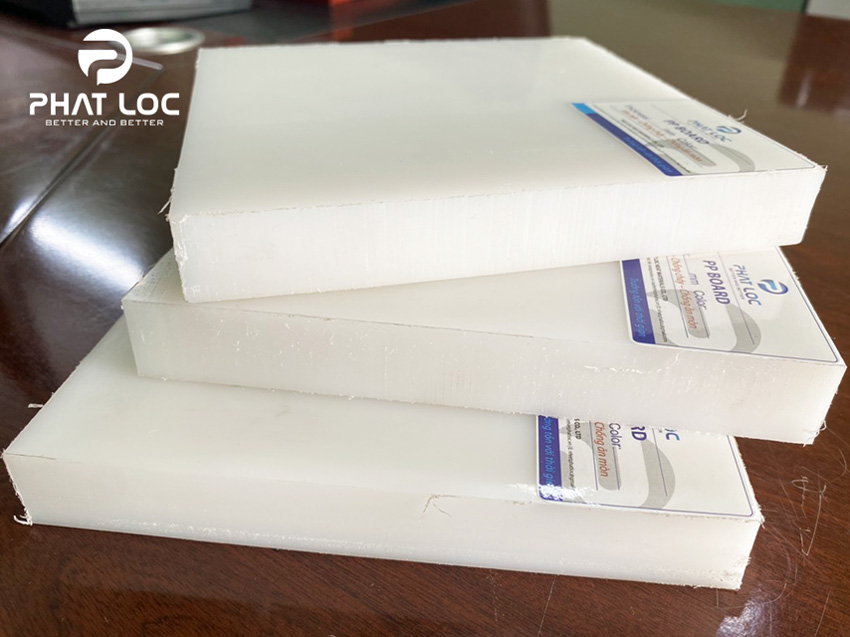

PP/PE technical plastic sheet

08.12.2021

The chemical properties of Polypropylen(PP) does not react with dilute bases and acids, which are often found in liquids, first-aid products, and cleaning agents. so This material to containers for liquids. ( chứa chất lỏng)

PP is an insulator. It is a great material for produce certain electronic components such as PP capacitors and audio equipment. Electric cables also use PP for insulation. ( cách điện )

PP responds to heat. PP will turn to liquid when it reaches its melting point. The liquid can then be molded into any desired shape. Injection molding uses polypropylene due to the way it responds to heat. It is also worth noting that PP can be heated, liquefied, cooled, and then reheated again without any significant degradation. The PP sheets are easy to put together by liquefying them, after the temperature returns to normal they will be seamless into 1 sheet. no any effect to quality( hàn PP, nên kèm ảnh )

PP has a high anti-corrosion and chemical leaching, it is the great choice for manufacturing piping systems. It has well avoided to freezing as well, so climatic conditions are not a problem when pipes are made using PP

PP can withstand heat in a pressure chamber or autoclave. it is a best material to design laboratories and make a medical box. It is even used to produce food box because it can withstand the heat in a dishwasher and microwase.

PP has high tensile strength and can go up to 4800 psi. That makes it a useful material in applications involving heavy loads and rugged use.

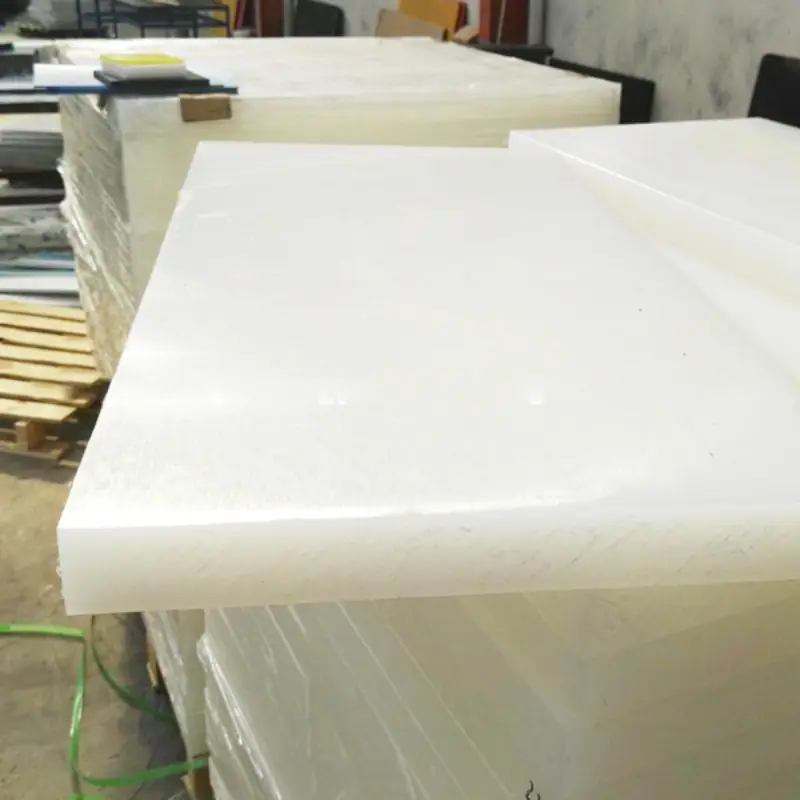

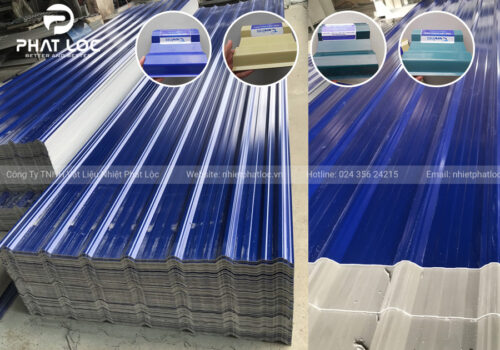

PP is an impermeable material. It will absorb less than 0.01% of water when soaked in it for 24 hours. This makes it an ideal material for products that are to be submerged in liquids. PP is used in the water-proofing of roofs as well. On the flip side, PP can be treated with certain chemicals to make it absorb water. In such cases, it can be used for making things like sanitary napkins and diapers.

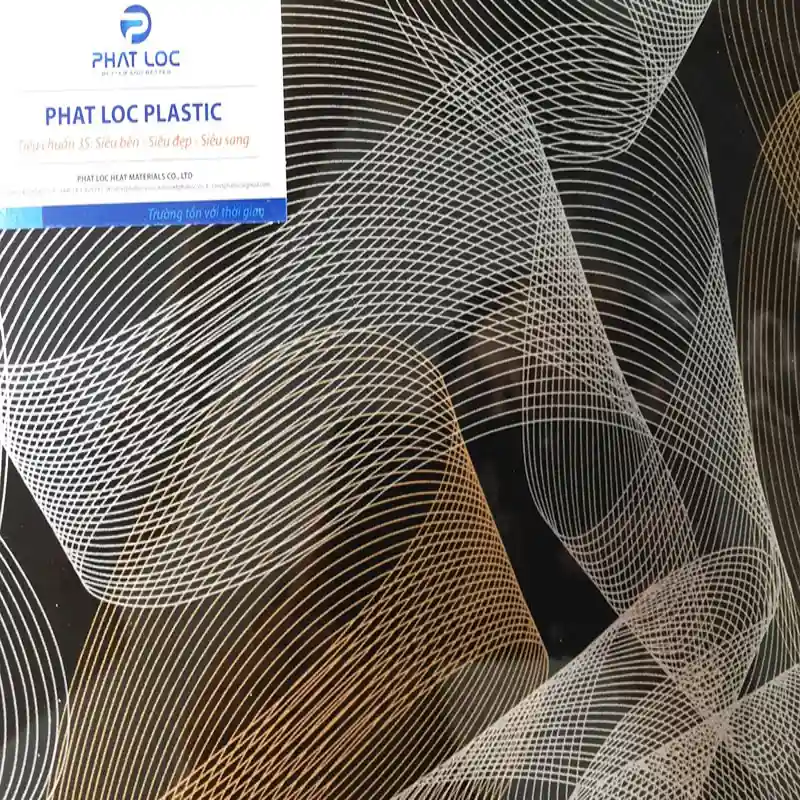

PP can be turned into a fiber form, which can allow for the making of mesh-like surfaces. Such surfaces are great for manufacturing filters used in water purification systems and air-conditioning systems.

PP has a low density as compared to other plastic materials. so it gives manufacturers the benefit of cost savings from the low weight.

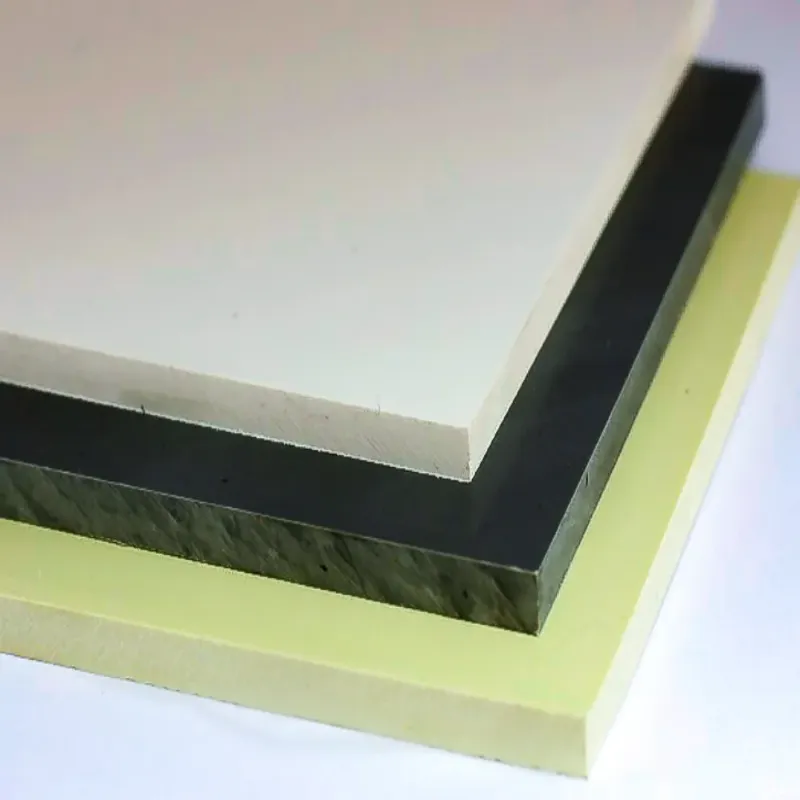

Specification

| STT | Các chỉ tiêu kỹ thuật/ specification | ĐVT / Unit | Thông số / Parameters |

| 1 | Độ bền kéo đứt/ tensile strength | N/cm2 | 2500 – 3200 |

| 2 | Độ dãn dài tương đối khi đứt/ Percentage elongation aller fracture | % | 25 – 33 |

| 3 | Độ bền uốn/ Bending strength | Mpa | 45 – 90 |

| 4 | Sự thay đổi kích thước trong 6h ở 55°C/ Percentage size change through 6h in 55°C | % | 0.01 – 0.1 |

| 5 | Nhiệt độ Vicat/ Vicat temperature |

°C | 100 |

| 6 | Độ dày/ Thickness | mm | 3-30 |

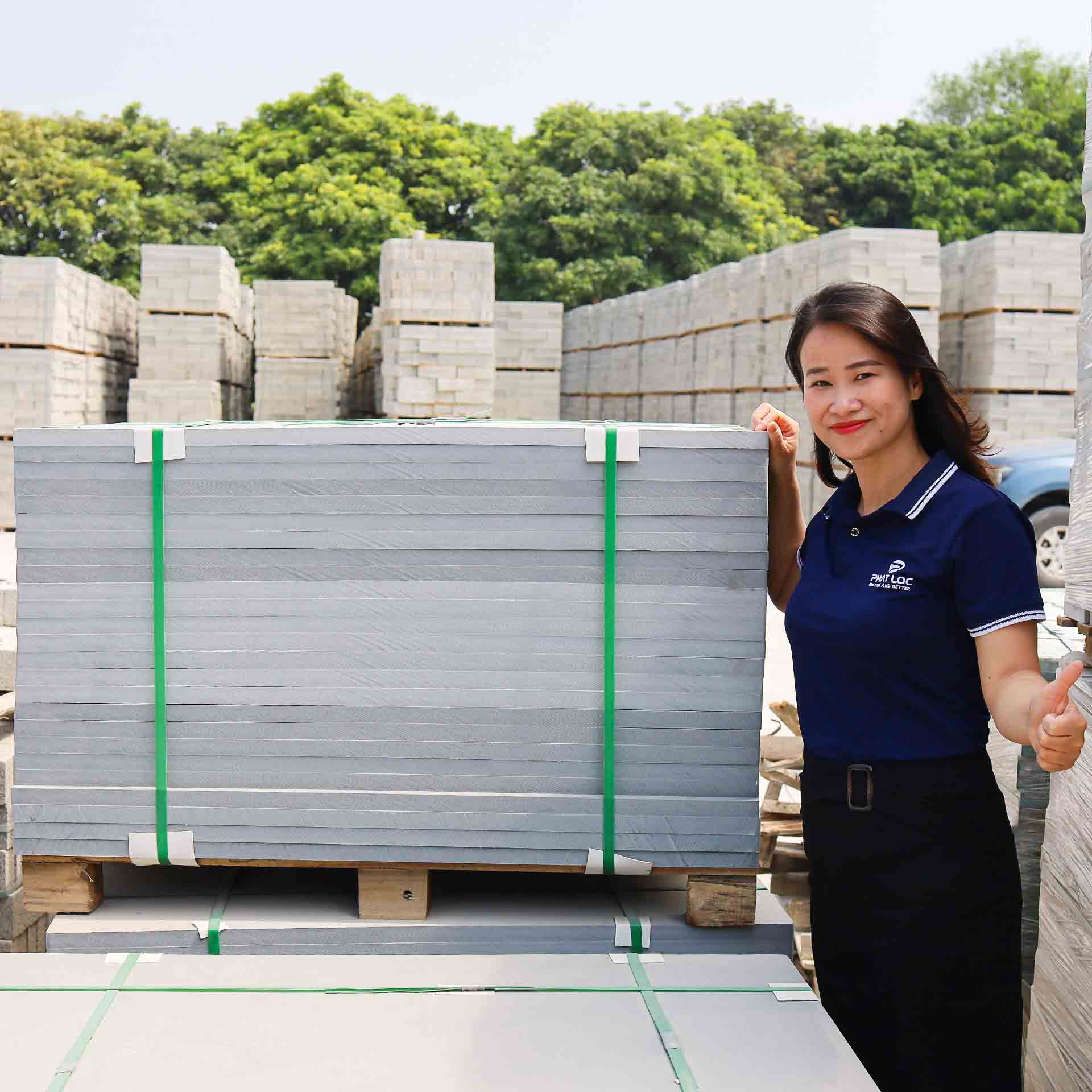

| 7 | Kích thước/ Size | Square meter | 1000mm*2000mm, 1220mm*2440mm |

| 8 | Màu sắc/ Color | Grey, white, etc | customers’ request |

Application

PP sheets are used in chemical industry, water treatment, food and pharmaceutical technology and interior decoration